We are striving to be the world’s leading in all our fields of expertise. Stay up to date for all that we share.

Root Cause Analysis and Sherlock Holmes: A Detective Approach to Technical Problem Solving

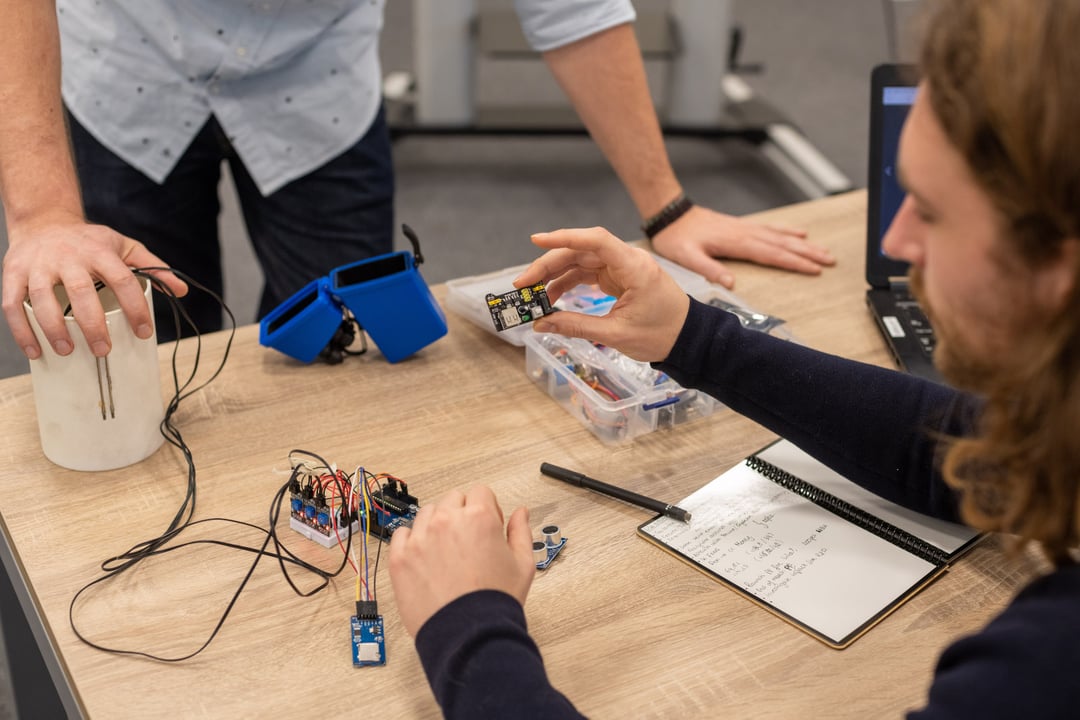

In the fast-paced world of high-tech and healthcare innovation, every detail matters. A tiny...

.jpg?width=200&name=Holland%20Innovative%20summer%20academy%20-%20Project%20Management%20Masterclass%202%20(2).jpg)